| |

| Diffusion amplifier wind turbine |

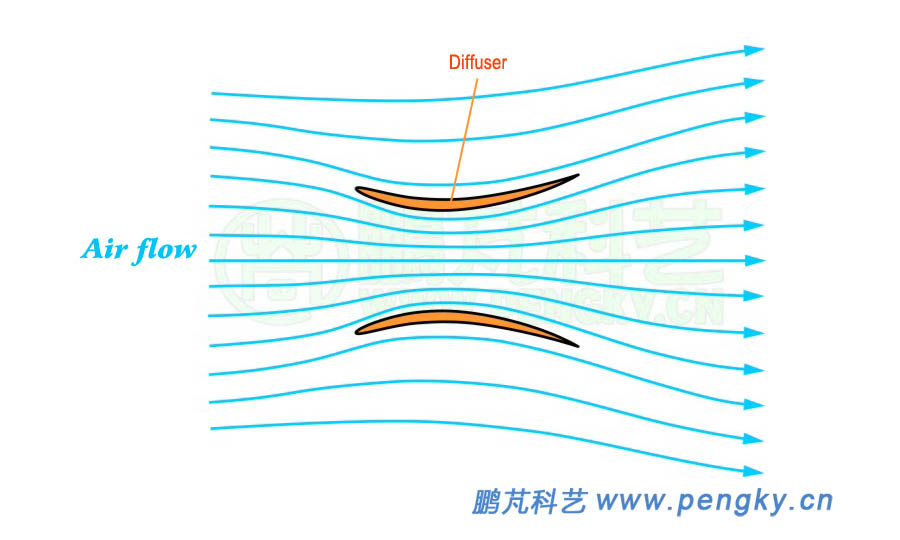

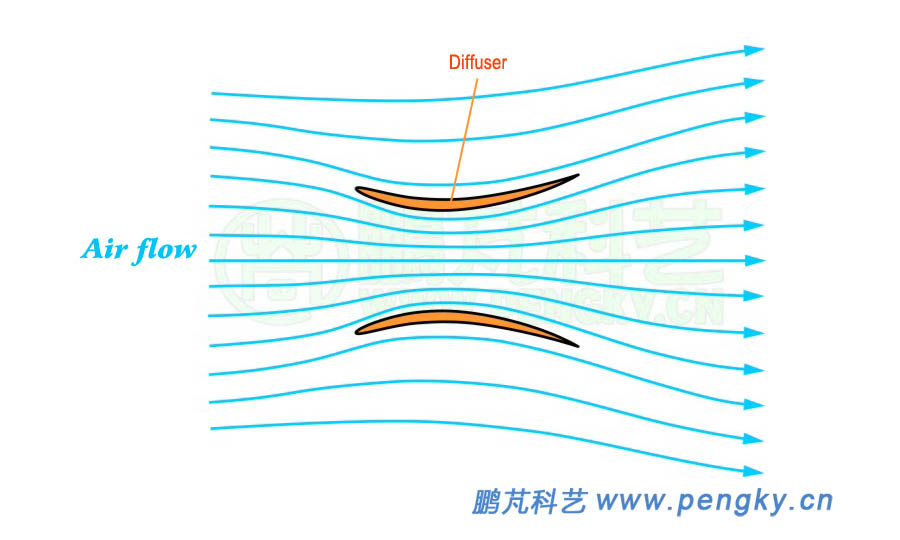

| We all know that the wind power is proportional to the third power of the wind speed. Is there any way to increase the wind speed? There are two convex sides relatively curved vanes that have a greater increase in velocity as the airflow flows between the two vanes. Figure 1 is a schematic illustration of the airflow. |

|

| Figure 1 - Schematic diagram of the diffuser airflow |

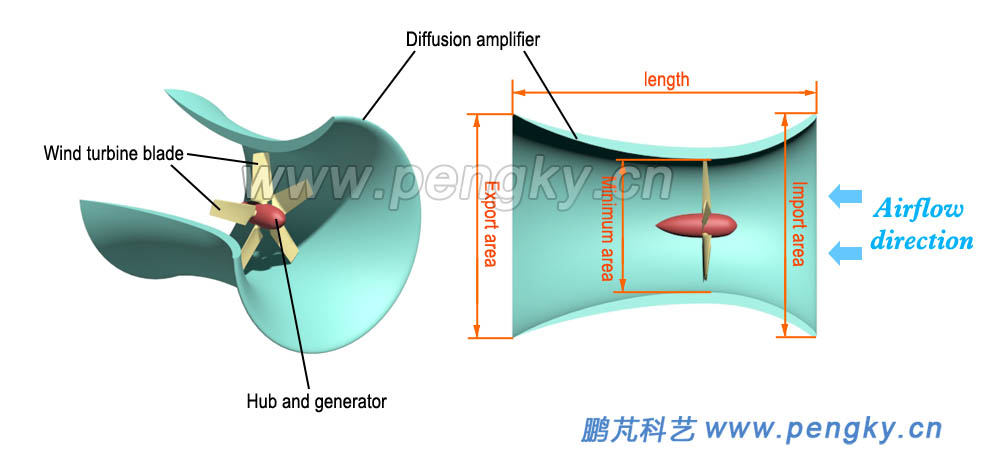

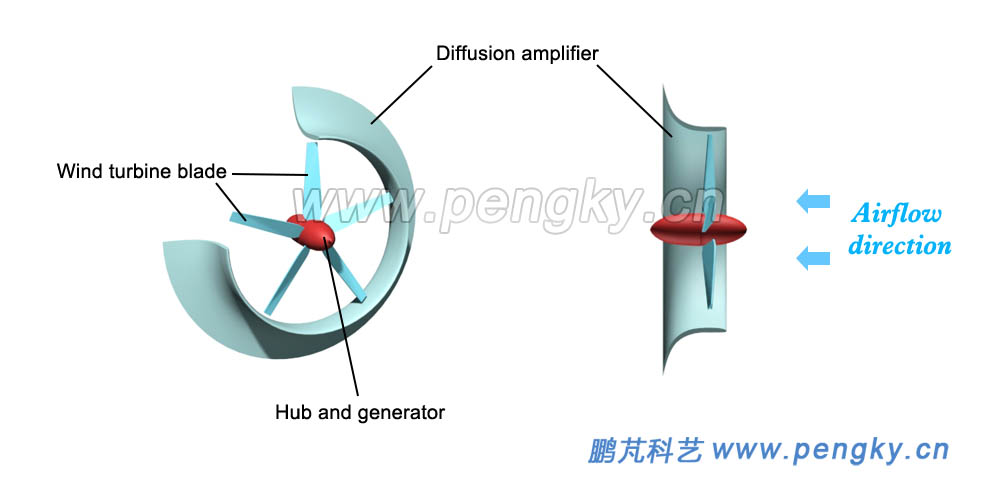

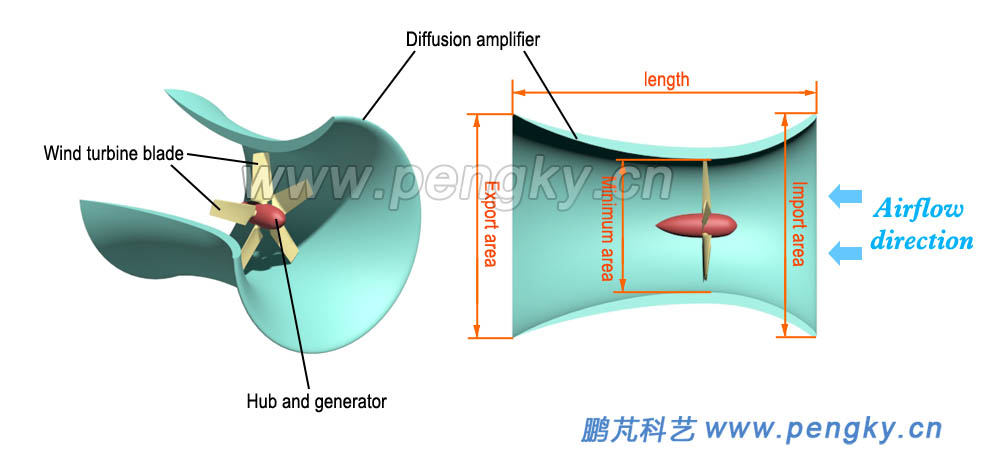

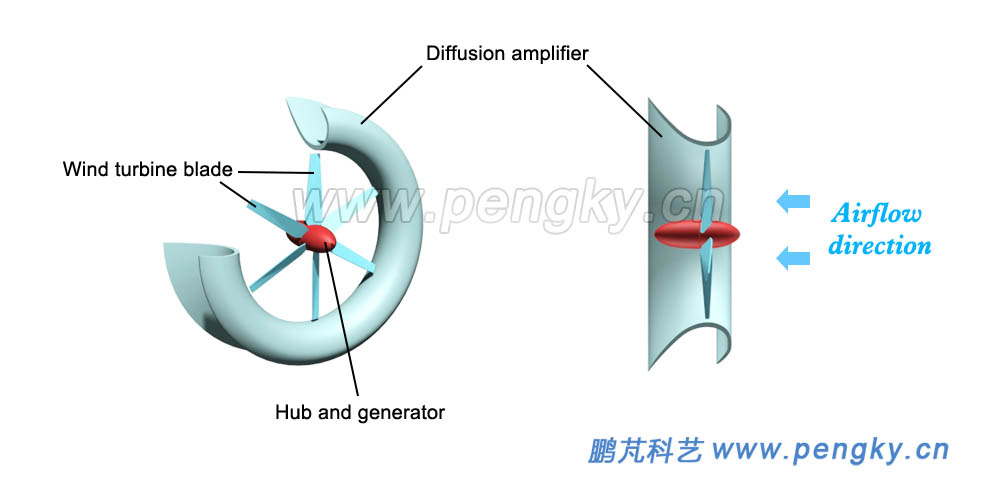

The cross section of a circle tube is made into the vane shown in figure 1, see figure 2, and the right side of the figure is a side sectional view of the tube, the cross section of which is the same as that of figure 1, and the left side of the figure is a three-dimensional sectional view of the tube. Call this tube a diffuser.

When the airflow flows through the pipe, the flow velocity at the minimum of the middle section is much faster than that outside the pipe. The wind rotor is installed at the minimum of the middle section. The wind rotor combined with the diffuser is called diffusion large sized wind turbine.

If the flow speed in the pipe can be increased by 10%, the wind power can be increased by 33.1%, which is equivalent to the wind energy utilization coefficient of the wind rotor rising to 133.1%, which is considerable. |

|

| Figure 2 - tapered divergent diffuser |

At present, there are two main types of diffusers commonly used, tapered and divergent and single divergent. Figure 2 shows a tapered and divergent diffuser. The airflow enters the diffuser and contraction first, then passes through the smallest section and then diffuses.

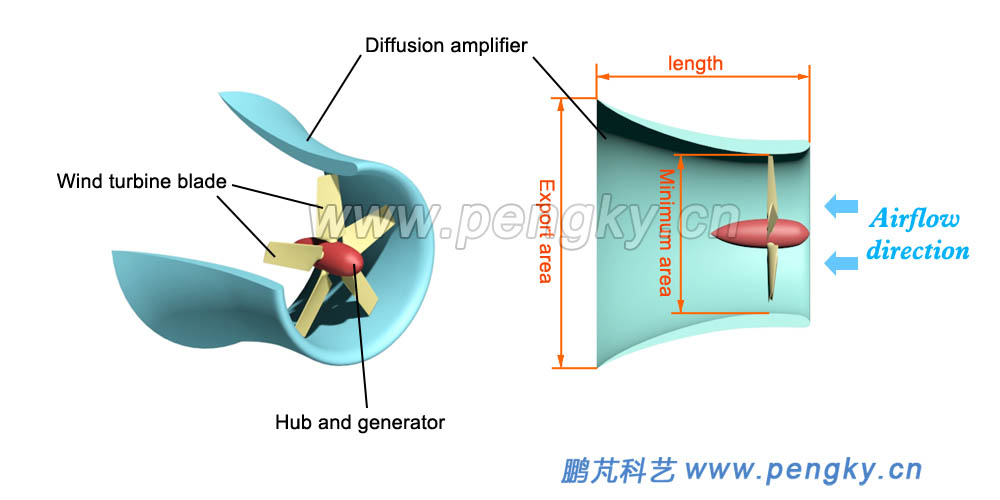

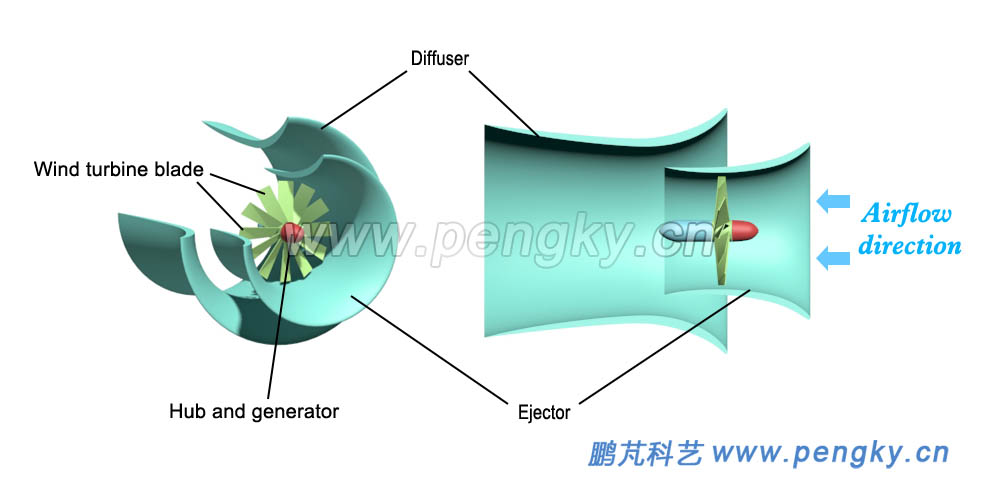

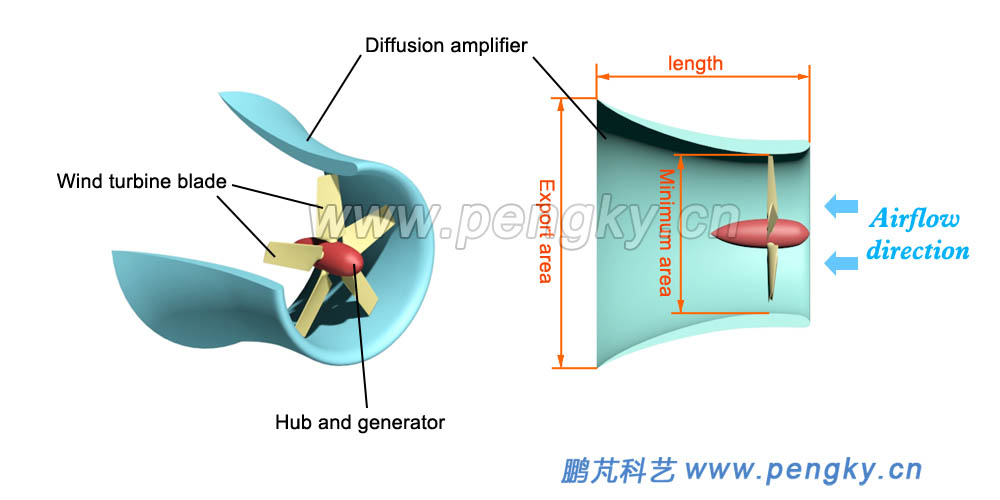

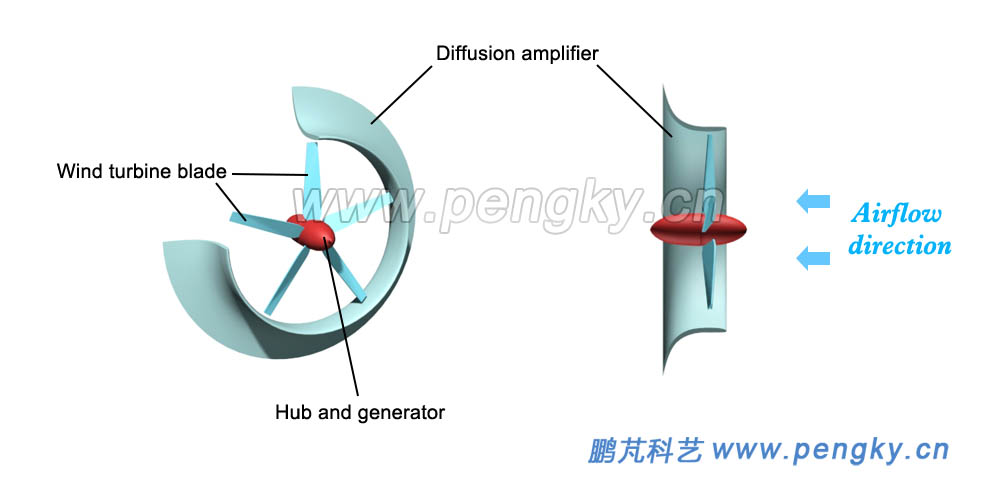

Shown in figure 3 is a single divergent diffuser, the right side of the figure is a side cross-sectional view of the tube, the left side of the figure is a three-dimensional cross-sectional view of the tube, the front end of the diffuser has no contraction, only the diffusing part of the rear, therefore, it is called a single divergent diffuser. After the airflow enters the diffuser, the airflow velocity is rapidly reduced due to the enlarged cross section of the pipe, so that the pressure difference between the front and the rear of the pipe is increased, and the airflow velocity at the inlet is increased. |

| Figure 3 - Single divergent diffuser |

The physical dimensions of the diffuser mainly include the minimum area, the exit area, the length, and the inlet area; the main properties index of the diffusion amplifier is the ratio of the flow rate at the minimum cross section to the inflow velocity (flow ratio). Generally, when the length is the same, the flow rate ratio increases as the ratio of the area of the outlet area to the minimum area increases; when the ratio of the outlet area to the minimum area is the same, an appropriate increase in the length can also increase the flow rate ratio; When the ratio of the outlet area to the minimum area is the same, the tapered divergence type is larger than the single diverging type flow rate ratio. In addition, the flow velocity is larger than the flow velocity, and the flow rate ratio is larger. All of the above are properties within a certain range of dimensional changes.

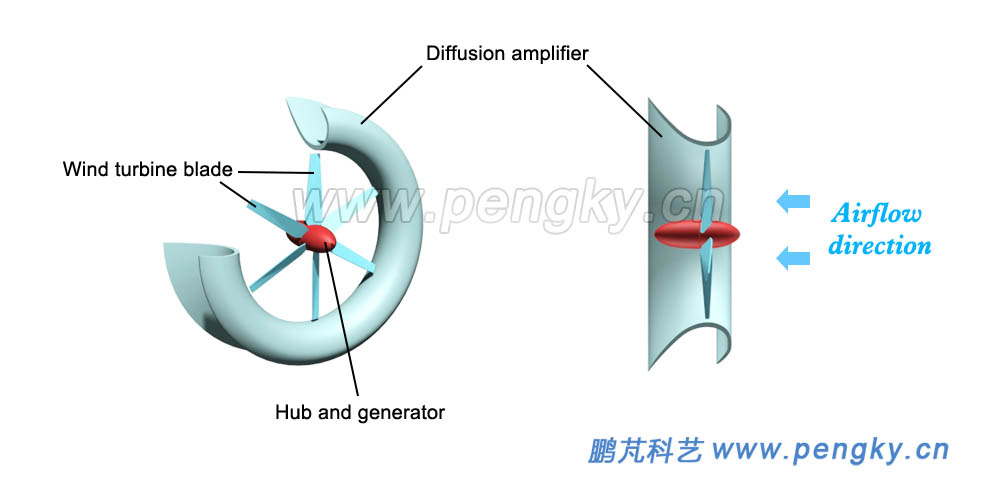

In practical applications, the use of a shorter diffusion tube can reduce production and installation costs, and can also achieve a certain speed increase effect. Figure 4 is a schematic diagram of a tapered tube with a tapered and divergent wind turbine. |

| Figure 4 - Shrinking and diverging wind turbine |

| Figure 5 is a schematic illustration of a single divergent diffuser wind turbine with a short tube. |

| Figure 5 - Single divergent diffuser wind energy conversion system |

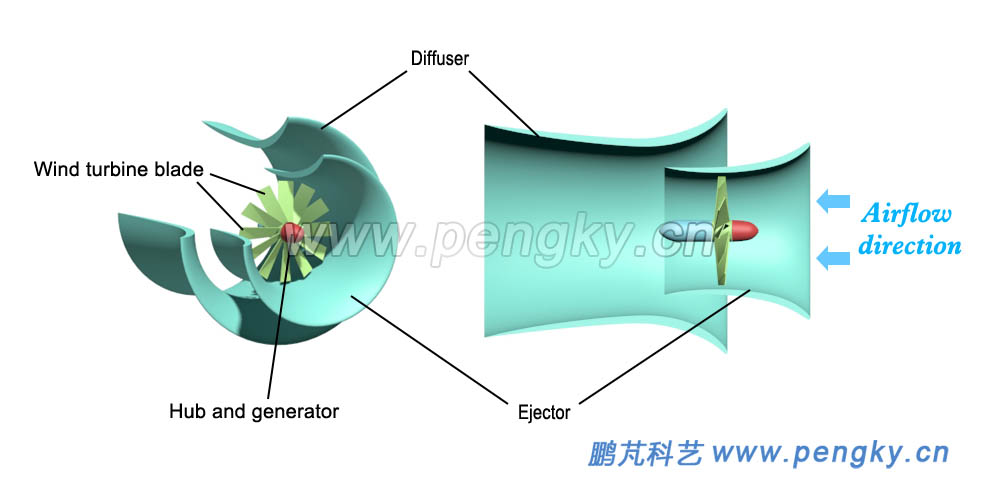

| As early as 1957, the famous Chinese scientist Xuesen Qian proposed the "wind tunnel windmill" scheme using a diffuser. The principle structure is shown in figure 6. The wind tunnel windmill consists of an ejector and a diffuser. This structure can form a large flow velocity. But the structure is more complicated, the current application is less, most of the ejector is omitted, only the diffuser is used, which is the two forms described above. |

| Figure 6 - Wind tunnel windmill schematic |

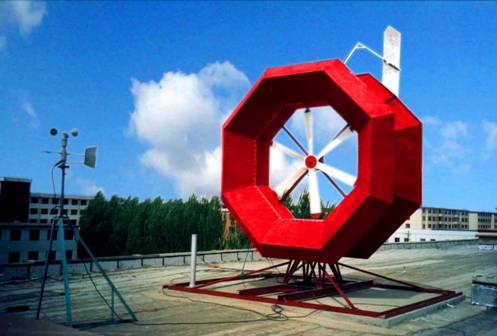

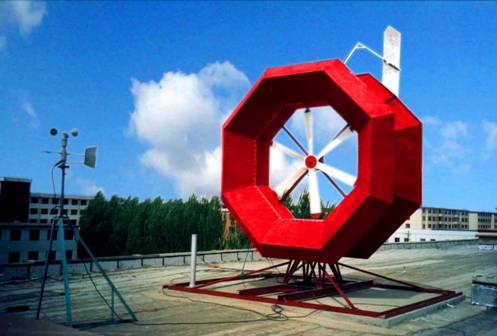

| The diffuser-type wind turbines must also obtain the maximum power for the wind. Except for the large-scale diffuser-type wind turbines, which use the wind-measuring machine to drive the wind, most of them adopt the automatic wind mode. Among them, the following wind type is used, that is, the wind is made by the resistance of the diffuser. Figure 7 is a diffuser-type wind turbine developed by a university in China. It uses tail vane to the wind. |

|

| Figure 7 - Diffusion wind turbine with tail rudder |

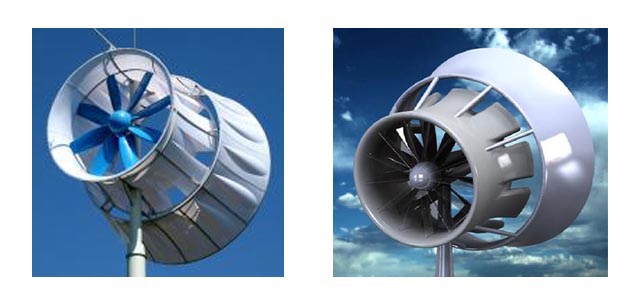

| Figures 8 and 9 are pictures of a foreign diffused wind turbine on the network. |

|

| Figure 8 Picture of a diffused wind turbine on the network (1) |

|

| Figure 9 Picture of a diffused wind turbine on the network (2) |

The diffusion type wind turbine can significantly improve the efficiency of the wind rotor. According to the relevant article, the wind rotor area of the 200W small diffusion type wind turbine developed by a university in China is 1.2 square meters, and the wind energy utilization coefficient is 0.52 when the wind speed is 10m. Well, much higher than ordinary wind turbines.

Although the diffused wind turbine can significantly improve the efficiency of the wind turbine, the diffuser increases the resistance to the wind, the weight of the diffuser increases the load on the tower, and the manufacturing and installation costs of the diffuser are significantly increased; The length of the blade to increase the output power of the wind rotor may be less costly. For wind turbines above MW, a diffuser with a diameter of several tens of meters is installed on a tens of meters high tower and can withstand strong winds. The project is huge and the cost will be very high. The first consideration for the commercial value of a wind turbine is the production and installation and maintenance costs of each 1 kW electric plant. Therefore, the current divergent wind turbines are only used for miniature and small wind turbines. Vertical axis wind turbines can also use diffusers to increase wind energy utilization. Vertical axis wind turbines with diffusers are commonly used in ocean current power generation.

Foreign inventors have used the method of a gas-filled diffuser to solve the problem of large diffusers. The diffuser filled with light gas floats in the air and is pulled by steel cables (with cables). The high wind speed in the air, and the expansion and speed increase, but also the automatic wind, really good, see figure 10. |

|

| Figure 10 - Diffusion wind turbine floating in the air |

However, the diffuser will float in the air for many years. The strength and toughness of the skin material should be guaranteed under the action of strong ultraviolet rays and strong winds for a long time. The materials that meet this requirement are still very expensive, and some safety measures should be considered comprehensively. At present, there are test models for small floating diffuser wind turbines abroad. For large wind turbines, it is necessary to wait for the development of material technology to realize the commercial application of floating diffuser wind turbines.

If a suitable building space is designed as a diffuser, it is a good application of the diffuser principle. Figure 11 is a successful example of forming a diffuser between two tall buildings and installing three sets of wind rotors. |

|

| Figure 11 - Diffuser formed using building space |

| |

|